Introduction to Fahad Cables Industry FZE

Fahad Cables Industry FZE, established in Sharjah, UAE, has rapidly become a leading name in the cable manufacturing sector. Founded with the vision to provide innovative and reliable cable solutions, the company is dedicated to serving a diverse clientele, ranging from construction companies to industrial applications. The strategic location in Sharjah allows Fahad Cables to efficiently cater to both domestic and international markets, fostering growth and enhancing accessibility for its products.

The mission of Fahad Cables Industry FZE revolves around delivering high-quality flexible cables that meet stringent industry standards. By employing advanced manufacturing processes and cutting-edge technology, the company ensures that its products consistently reflect durability, reliability, and safety. The commitment to excellence is evident in every stage of production, from sourcing premium raw materials to final inspections before delivery. This meticulous attention to detail has established Fahad Cables as a trusted partner in the cable supply chain.

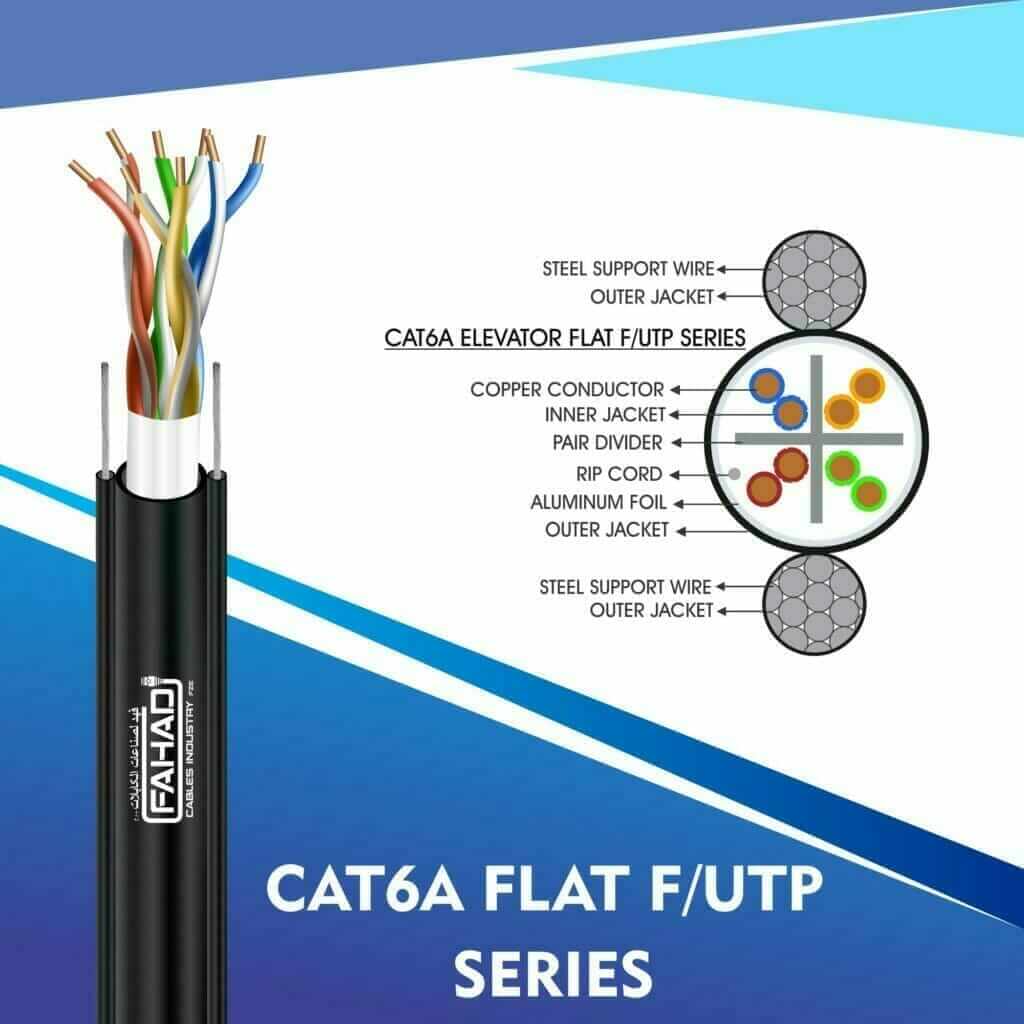

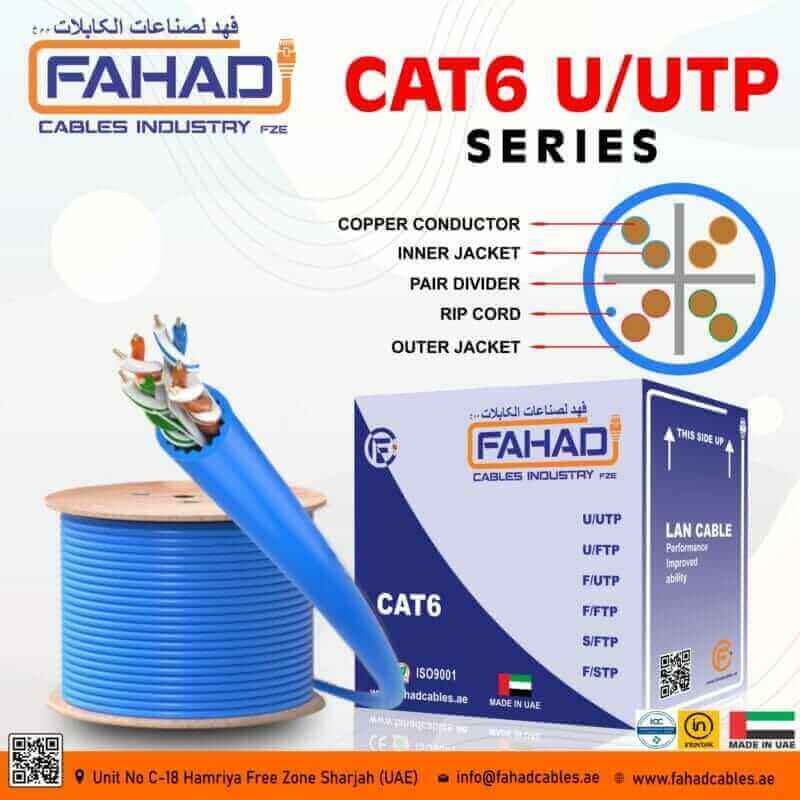

Fahad Cables specializes in a wide array of products, including but not limited to power cables, control cables, and instrumentation cables. Each category is designed to meet the specific needs of various industries, ensuring versatility and performance. The organization’s focus on research and development enables it to adapt to evolving market demands and incorporate the latest advancements in cable technology. Furthermore, Fahad Cables prioritizes sustainable practices in its manufacturing processes, aligning with global environmental standards.

Overall, Fahad Cables Industry FZE exemplifies a blend of innovation, quality, and customer satisfaction in the cable manufacturing landscape. Its unwavering commitment to excellence positions the company as a front-runner in the competitive market of flexible cables in the UAE and beyond.

Understanding Flexible Cables and Wires

Flexible cables and wires are electrical conductors designed to easily bend and twist without losing functionality. Unlike standard cables, which may be rigid and prone to breaking under stress, flexible cables possess the inherent ability to withstand substantial movement and manipulation. This characteristic makes them invaluable in various industries, where they are employed in applications that necessitate movement or dynamic usage.

The construction of flexible cables is distinguished by the use of multiple strands of fine wire, as opposed to a single solid conductor. This specific design ensures that the cables maintain their integrity and performance, even when subjected to repeated flexing or twisting. Moreover, the materials used in the insulation and sheathing of flexible cables greatly contribute to their resilience, giving them the capability to resist harsh environmental conditions, such as moisture, chemicals, and temperature fluctuations.

One of the primary reasons flexible cables are preferred in numerous applications is their versatility. They can be utilized in a wide range of settings, including residential, commercial, and industrial environments. For instance, you may find them in electronic devices, power tools, automotive technology, and even robotics. Their adaptability allows them to navigate through tight spaces and around obstacles, making them ideal for projects that call for intricate wiring configurations.

Additionally, the durability of these cables enhances their long-term reliability. Flexible cables are designed to endure fatigue over time, ensuring that they can handle continuous motion without experiencing performance degradation. As technology advances and the demand for more dynamic wiring solutions increases, understanding the distinct advantages of flexible cables becomes essential for both manufacturers and consumers seeking quality electrical connections.

Key Applications of Flexible Cables

Flexible cables are integral components in various industries due to their versatility and efficiency. One of the primary sectors utilizing flexible cables is construction. In this domain, these cables facilitate reliable electrical connections and are essential for powering tools and machinery onsite. For instance, temporary power supplies often rely on flexible cables that can be easily maneuvered around construction sites, allowing workers to maintain productivity without constraints.

Another significant application is found in the automotive industry. Flexible cables streamline the operation of various vehicle systems, such as electrical controls, sensors, and lighting. The adaptability of these cables enables manufacturers to design complex wiring harnesses that can withstand vibrations and movement, essential for vehicle performance and safety. For example, flexible cables are commonly employed in electric vehicles to connect battery systems with motors, ensuring efficiency in energy transfer and reducing potential failures.

The telecommunications sector also prominently features flexible cables, where they are employed to establish robust data connections. Utilizing flexible cables for connecting devices facilitates easier installation and maintenance, enhancing overall communication infrastructures. With the growing demand for high-speed internet and data transmission, these cables serve as vital links between network devices, supporting seamless connectivity.

Additionally, the renewable energy industry increasingly turns to flexible cables. These cables are essential for connecting solar panels to inverters and storage systems in photovoltaic setups. Their durability allows them to perform efficiently in various environmental conditions, making them a preferred choice for renewable applications. The flexibility of these cables helps streamline installations, adapt to diverse layouts, and improve the safety of electrical systems.

In various industries, the adaptability and reliability of flexible cables are indispensable. Their unique properties not only enhance functionality but also significantly contribute to the safety of electrical systems across sectors.

Manufacturing Process of Flexible Cables at Fahad Cables

The production of flexible cables at Fahad Cables Industry FZE in Sharjah, UAE, involves a meticulous manufacturing process designed to ensure high quality and reliability. The first critical stage in the process is material selection. Fahad Cables prioritizes the use of high-grade raw materials, including premium copper for conductors and resilient thermoplastic or thermoset polymers for insulation. This careful selection guarantees durability, flexibility, and electrical conductivity, which are essential attributes of top-tier flexible cables.

Following material selection, the design phase commences. Expert engineers at Fahad Cables utilize advanced design software to develop cable specifications tailored to various applications. This includes determining the appropriate gauge, number of conductors, and insulation thickness. This planning phase also considers factors such as environmental conditions and compliance with international standards, ensuring that the final product is reliable in diverse settings.

Once the design is approved, the manufacturing process transitions to extrusion. In this stage, the selected materials are fed into specialized extrusion machines where they are heated and formed into the desired shape. The process involves the careful layering of insulation around the conductor to produce cables that meet both flexibility requirements and mechanical strength. Automated systems monitor temperature and pressure levels to ensure consistency throughout production.

The final stage of the manufacturing process is quality control. Fahad Cables employs a stringent quality assurance system that incorporates both automated and manual inspections at various stages of production. This ensures compliance with international standards and industry regulations. Samples of finished products undergo rigorous testing to check electrical performance, mechanical strength, and flexibility. By adhering to these meticulous processes, Fahad Cables guarantees that their flexible cables not only meet but exceed market expectations for safety and efficacy.

Quality Control and Certifications

Quality control is a paramount aspect of the production process, particularly for industries such as cable manufacturing where safety and reliability are non-negotiable. At Fahad Cables Industry FZE, the dedication to high-quality standards is reflected in their rigorous quality control measures. The company follows a systematic approach that begins with the selection of raw materials, extending through the manufacturing processes, and culminating in thorough testing before product distribution.

To ensure compliance with international benchmarks, Fahad Cables has obtained a number of esteemed certifications, including various ISO standards. These certifications not only validate the quality of their products but also signify a comprehensive understanding of global best practices in manufacturing. The ISO 9001 certification, for instance, speaks to their commitment towards maintaining an effective quality management system that guarantees customer satisfaction. The adherence to these standards ensures that every flexible cable produced meets strict reliability and safety protocols, which are crucial for many applications, whether in residential or industrial settings.

The significance of testing protocols cannot be overstated in the cable manufacturing industry. Fahad Cables conducts meticulous testing at various stages, which includes assessments of electrical performance, thermal resistance, and mechanical durability. These tests ensure that the flexible cables can withstand various environmental conditions and mechanical stresses they may encounter in real-life applications. By implementing these robust quality control measures, they are able to deliver products that not only comply with regulatory requirements but also exceed the expectations of their customers.

Overall, the emphasis on quality control and adherence to recognized certifications positions Fahad Cables as a reliable and trustworthy manufacturer in the competitive market of flexible cables.

Innovations and Technological Advancements

Fahad Cables Industry FZE has consistently demonstrated a commitment to incorporating innovations and technological advancements into its manufacturing processes. This dedication is evident in the adoption of modern machinery that enhances efficiency and production capabilities. The company has invested in state-of-the-art equipment designed to optimize the precision and quality of production, thereby ensuring that the flexible cables meet international standards. By employing automated systems, Fahad Cables can streamline operations, reduce manufacture time, and increase overall productivity.

Moreover, the choice of materials used in the manufacturing of flexible cables plays a critical role in the company’s innovation strategy. Fahad Cables has prioritized the use of advanced materials that not only improve the performance of its products but also enhance their durability and flexibility. For instance, the integration of high-grade polymers and conductive materials enables the production of cables that are not only lightweight but also capable of withstanding extreme environmental conditions. Such advancements ensure the cables remain reliable for various applications, from residential to industrial use.

In addition to focusing on materials and machinery, Fahad Cables recognizes the importance of sustainable practices in the manufacturing sector. The company actively seeks to minimize its environmental footprint by implementing eco-friendly processes and materials. This includes recycling initiatives and energy-efficient operations that contribute to sustainability in cable production. This commitment not only fulfills ethical obligations but also aligns with global trends toward greener manufacturing practices. Through these innovations and advancements, Fahad Cables Industry FZE reinforces its position as a leader in the flexible cable industry while catering to the evolving demands of the market.

Customer Satisfaction and After-Sales Support

Fahad Cables Industry FZE is committed to ensuring that customer satisfaction remains a central focus within their operations. By providing high-quality flexible cables, the company aims to meet and exceed the expectations of clients in diverse industries. The significance of customer satisfaction extends beyond just the sale of products; it encompasses a holistic approach that includes robust after-sales support. This support is essential to nurturing long-term relationships with clients and solidifying their confidence in the brand.

One of the primary aspects of after-sales support at Fahad Cables is assistance with product selection. Understanding that the right choice of cables can critically affect overall project efficiency, the company provides expert guidance to help customers choose the most suitable products for their specific requirements. This personalized approach not only informs clients about the technical specifications but also ensures they make informed decisions that align with their project objectives.

Installation guidance is another crucial component of Fahad Cables’ commitment to customer satisfaction. Recognizing that the installation of flexible cables can often present challenges, the company offers resources and support to facilitate a smooth and effective installation process. By sharing best practices and techniques, Fahad Cables empowers clients to maximize the performance of their cables, ensuring safety and reliability in their applications.

Moreover, the responsive customer service team at Fahad Cables plays a vital role in addressing any issues that may arise post-purchase. Clients can expect prompt responses to inquiries, assistance with troubleshooting, and a willingness to resolve problems effectively. This level of care contributes to heightened customer satisfaction and reinforces client trust in Fahad’s products and services. Overall, the combination of expert support in product selection, installation, and ongoing assistance reflects Fahad Cables’ dedication to quality and customer fulfillment.

Future Growth and Expansion Plans

Fahad Cables Industry FZE is poised for significant growth and expansion in the coming years, driven by a strong commitment to innovation and adaptation to market demands. As the global cable manufacturing industry continues to evolve, the company recognizes the importance of diversifying its market presence. This strategy includes penetrating emerging markets in regions such as Africa and Southeast Asia, where the demand for high-quality flexible cables is rapidly increasing. By establishing a foothold in these markets, Fahad Cables Industry aims to broaden its customer base and ensure long-term sustainability.

In addition to exploring new geographical locations, Fahad Cables Industry FZE is focused on expanding its product line. The company intends to enhance its offerings by developing new variants of flexible cables tailored to meet the specific needs of different industries, including construction, telecommunications, and renewable energy. This expansion will not only cater to the evolving requirements of existing clients but will also attract new customers looking for innovative solutions.

The vision for the future also emphasizes automation and technological advancement in the manufacturing processes. Fahad Cables Industry FZE plans to invest in state-of-the-art machinery that will enhance efficiency and product quality. By embracing cutting-edge technology, the company seeks to minimize production costs while maximizing output, ultimately leading to a competitive advantage in the market.

Moreover, fostering partnerships with key stakeholders in the cable industry will be crucial for Fahad Cables Industry FZE’s growth trajectory. Collaborations with suppliers, distributors, and research institutions will enable the company to stay ahead of industry trends and respond swiftly to changes. Overall, the future for Fahad Cables Industry FZE appears promising, with strategic growth initiatives that position it to thrive in the global cable manufacturing landscape.

Conclusion

Fahad Cables Industry FZE has made significant contributions to the flexible cables market, establishing itself as a pivotal player in the cable manufacturing sector in Sharjah, UAE. The company’s commitment to quality manufacturing ensures that their products not only meet but often exceed industry standards, catering to a diverse array of applications. This dedication to excellence has positioned Fahad Cables as a trusted name among consumers, both locally and internationally.

Innovation plays a crucial role in Fahad Cables’ operational strategy. The company continuously invests in advancing its technology and processes, ensuring that they remain at the forefront of the cable manufacturing industry. This proactive approach allows them to develop flexible cables that exhibit durability, efficiency, and adaptability to various environmental conditions. The integration of cutting-edge manufacturing techniques enables Fahad Cables to produce solutions that satisfy the evolving demands of modern industries.

Furthermore, customer service is a fundamental aspect of Fahad Cables’ business model. The company prioritizes understanding client needs, providing tailored solutions that align perfectly with specific requirements. By maintaining strong relationships with customers, they ensure product satisfaction and build long-term partnerships that are vital for sustained success. The dedicated service extends beyond sales; it encompasses ongoing support and advice, reinforcing the company’s commitment to its clientele.

In summary, the role of Fahad Cables Industry FZE in the cable industry cannot be overstated. Through quality manufacturing, innovative practices, and exceptional customer service, they have solidified their position as a leader in the flexible cables market. Their contributions not only enhance the industry standards but also promote the broader growth of the cable manufacturing landscape in the UAE and beyond.