Blog

cat 6 cable for elevator by fahad cables industry fze

Introduction to cat 6 cable for elevator

Cat 6 cables, commonly referred to as Category 6 cables, are a type of twisted pair cable that has become a standard in modern telecommunications. These cables are designed to support high-speed data transfer, offering enhanced performance over their predecessors like Cat 5 and Cat 5e. With a maximum data rate of 10 Gbps and a frequency of up to 250 MHz, Cat 6 cables are particularly suited for demanding applications requiring swift and reliable connectivity.cat 5 vs cat 6 vs cat 7

The construction of Cat 6 cables involves tighter twists in the pairs of wires, which serves to reduce crosstalk and system noise. This notable feature not only improves signal cat 6 cable benefits quality but also increases the distance over which data can be transmitted efficiently, making it ideal for installations in various settings, including commercial buildings and residential applications. An important aspect of Cat 6 cables is their ability to handle bandwidth-intensive applications, which is critical in an era where high-speed internet usage continues to rise dramatically.

straight cable color code

One of the key advantages of using Cat 6 cables is their adaptability, particularly in high-speed data transfer scenarios. In elevator systems, for example, the efficient transfer internet companies of data can be vital. Elevators increasingly rely on sophisticated technology that necessitates robust communications to ensure smooth operation and safety. Cat 6 cables provide the necessary infrastructure to support such technologies, allowing for efficient communication between control systems, monitoring devices, and user interfaces.cat 6 cable for elevator

In summary, Cat 6 cables represent a significant advancement in telecommunications technology. Their superior specifications make them a preferred choice for a variety of applications, especially in environments where high data transfer rates are essential, such as in elevator systems manufactured by industry leaders like Fahad Cables Industry FZE in the UAE.cat 6 cable for elevator

The Significance of Elevators in Modern Architecture

Elevators have become a pivotal element in modern architecture, transforming the design and functionality of multi-story buildings. As cities expand vertically, the need for efficient and reliable vertical transportation solutions has emerged as a critical concern for architects and developers. Elevators facilitate accessibility, ensuring that all individuals, regardless of physical ability, can navigate through structures seamlessly. This accessibility feature is particularly significant in commercial, residential, and public buildings, where the movement of people is frequent and varied.cat 6 cable for elevator

The integration of elevators within architectural designs not only enhances the user experience but also contributes significantly to the overall efficiency of building operations. cat 6 cable for elevator Elevators must be carefully planned and strategically placed within a structure to optimize traffic flow and minimize wait times. In today’s world, where urban environments become increasingly dense, the role of elevators extends beyond mere convenience; they are essential for ensuring the building’s functionality in serving its occupants.cat 6 cable for elevator

Furthermore, as technology continues to advance, elevators are increasingly equipped with smart systems that enhance their performance and reliability. Modern elevators often utilize sophisticated data connections to monitor their operational status and respond to usage patterns. This necessitates the deployment of cat 6 cable for elevator quality cabling solutions, such as Cat 6 cables, to support high-speed data transfer and communication between various elevator components. The integration of these advanced technologies not only improves safety measures and operational efficiency but also adds to the building’s overall appeal and marketability.cat 6 cable for elevator

In summary, elevators represent a crucial aspect of modern architectural design. Their role in enhancing accessibility and improving the flow of occupants within multi-story structures cannot be underestimated. With the continual advancement in technology, ensuring reliable data connectivity through quality cabling solutions is essential to maintain these essential conveyance systems, underscoring the significance of elevators in contemporary architectural practices.cat 6 cable for elevator

Why Cat 6 Cables Are Ideal for Elevator Systems

In the realm of elevator systems, the integration of advanced technology is paramount for ensuring efficient and reliable operations. This is where Cat 6 cables emerge as a vital component. Designed to support high-speed data transmission, Cat 6 cables provide a bandwidth capability of up to 250 MHz, making them well-suited for the demanding requirements of modern elevator control systems. These cables facilitate seamless communication between various components, cat 6 cable for elevator ensuring that data transfer occurs without delay, which is crucial for effective elevator functioning.

One of the primary advantages of Cat 6 cables is their reduced interference capabilities. Equipped with improved shielding compared to previous standards, these cables minimize crosstalk and external interference. This characteristic is especially important in environments where multiple devices and signal sources may lead to disruptions. For elevator systems that increasingly rely on smart technology, such as IoT devices and advanced control systems, the ability to maintain a clear signal is essential for operational reliability and safety.cat 6 cable for elevator

Moreover, Cat 6 cables excel at handling multiple devices simultaneously. With the rise of smart elevators that incorporate a variety of features, including remote monitoring, user interfaces, and security systems, the ability to transmit data from several sources without compromising performance becomes essential. The structure of Cat 6 cables allows for the integration of these diverse systems, ensuring that elevators can operate efficiently while handling large volumes of data traffic.cat 6 cable for elevator

In conclusion, the adoption of Cat 6 cables in elevator systems offers significant advantages, including high-speed data transmission, reduced interference, and efficient handling of multiple devices. These qualities not only enhance the performance of elevator control systems but also support the implementation of innovative features that improve user experience and operational efficiency.cat 6 cable for elevator

Fahad Cables Industry FZE: A Leader in Cable Manufacturing

Fahad Cables Industry FZE stands out as a premier manufacturer of cables in the UAE, earning a reputation for excellence in the field of electrical and communication cables. Established with a vision to address the evolving demands of the regional market, the company has been pivotal in delivering high-quality products, including Cat 6 cables tailored for various applications, including elevators. The organization prioritizes both innovation and quality, ensuring that its offerings meet stringent international standards.

The company’s commitment to quality is evident in its manufacturing processes, which adhere to the highest industry norms. Fahad Cables Industry FZE employs advanced technology and materials, ensuring cat 6 cable for elevator that every cable produced is resistant to wear and tear, offers outstanding performance, and accommodates the rigorous requirements often associated with modern infrastructural development. This focus on quality translates into a wide-ranging portfolio capable of serving diverse sectors, including telecommunications, construction, and industrial applications.cat 6 cable for elevator

Moreover, Fahad Cables maintains a forward-thinking approach by investing in research and development to innovate and improve its product line continually. This drive for innovation has positioned the company as a leader in the market, allowing it to respond effectively to both local and international demands. The Cat 6 cables are a prime example of this commitment, designed to deliver superior data transmission capabilities and enhanced performance for various applications, including elevators—an essential element for modern building functionality.

Fahad Cables Industry FZE is not only recognized for its quality and innovation, but its customer-centric approach also strengthens its market standing. By offering tailored solutions and extensive support, the company enhances client satisfaction, establishing long-term relationships built on trust and reliability. Hence, it is evident why Fahad Cables remains a vital player in the cable manufacturing industry in the UAE.cat 6 cable for elevator

Manufacturing Process of Cat 6 Cables

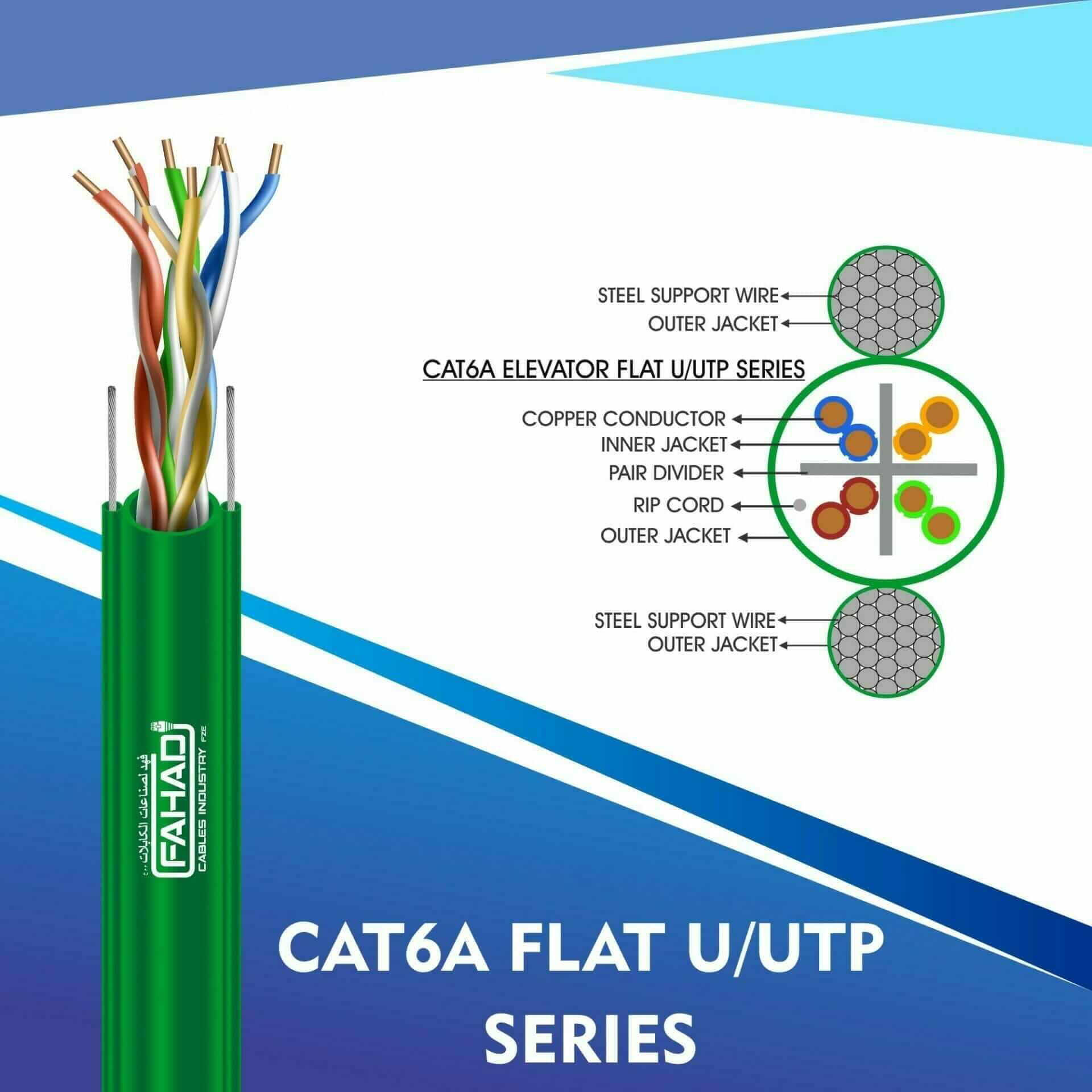

The manufacturing of Cat 6 cables at Fahad Cables Industry FZE is a meticulous process that ensures high-quality and durable products. The journey begins with the careful selection of raw materials, which is crucial for the transmission performance of the cables. Copper conductors are chosen for their excellent electrical conductivity, while high-density polyethylene (HDPE) and low smoke zero halogen (LSZH) materials are employed for insulation and sheathing. These materials not only enhance the cable’s performance but also contribute to safety in environments such as elevators, where fire resistance is a priority.cat 6 cable for elevator

Once the materials are selected, the production phase commences. The manufacturing process involves a series of steps starting with wire drawing where copper wire is reduced to the desired thickness. This is followed by the insulation process, where each conductor is coated with HDPE or LSZH to prevent signal interference. After the insulation, the twisted pair formation takes place. Each pair is twisted together in a specific pattern to minimize crosstalk and electromagnetic interference, essential attributes for CAT 6 performance standards.cat 6 cable for elevator

Following the twisting, the cables undergo a stranding process, where the pairs are combined to form a cable core. At this stage, an additional shielding layer, if required, is applied to enhance resistance to outside interference. The cables are then subjected to rigorous quality control measures. Testing for electrical performance, structural integrity, and compliance with national and international standards is paramount. This stage ensures that each cable produced meets high standards for both durability and efficiency.cat 6 cable for elevator

By integrating advanced technology and stringent quality control throughout the manufacturing process, Fahad Cables Industry FZE guarantees the reliability and effectiveness of their Cat 6 cables. Their commitment to quality ensures that these cables can withstand the demands of modern elevator installations, providing efficient data transmission in a variety of applications.cat 6 cable for elevator

Installation Best Practices for Cat 6 Cables in Elevators

The installation of Cat 6 cables in elevator systems requires careful consideration to ensure optimal performance and longevity. Proper installation techniques play a crucial role in minimizing signal interference and adhering to safety standards. First and foremost, it is essential to select the appropriate route for laying the cables. This involves planning the path that the cables will take from the control room to the elevator shaft, ensuring that the route avoids exposure to potential sources of electromagnetic interference, such as electrical equipment or fluorescent lighting.

Another critical aspect is cable management. Utilizing cable trays or conduits can help maintain organization and ensure that cables are secured properly without excessive bending or twisting, which could impair signal quality. Moreover, it is advisable to avoid running Cat 6 cables in proximity to power lines or high-voltage equipment, as this can negatively impact performance due to electromagnetic interference. Furthermore, when installing the cables, maintain a minimum bend radius specified by the manufacturer to prevent damage and degradation over time.cat 6 cable for elevator

Additionally, when connecting Cat 6 cables to other equipment, such as switches or routers within the elevator control system, it is important to use high-quality connectors. Proper termination techniques should be followed to mitigate issues related to attenuation and crosstalk, which can reduce the overall efficiency of the system. Testing the installation with appropriate tools, such as cable testers, before finalizing the setup can help ensure that the cables are functioning as expected.

Compliance with relevant safety standards and local building regulations is vital during the installation process. This ensures not only operational efficiency but also the safety of maintenance personnel who may interact with the cables in the future. By following these best practices in the installation of Cat 6 cables within elevator systems, one can guarantee a reliable and efficient communication infrastructure that meets contemporary demands.cat 6 cable for elevator

Comparing Cat 6 with Other Cable Types for Elevators

The selection of cables for elevator systems is critical, as it directly impacts performance, reliability, and data transmission efficiency. In this context, Cat 6 cables, manufactured by Fahad Cables Industry FZE in the UAE, present several advantages when compared to other types of cables, including Cat 5e and fiber optic cables.cat 6 cable for elevator

Starting with Cat 5e, this cable type has been widely used in various applications due to its affordability and adequacy for basic data transmission. However, when discussing elevator systems, Cat 5e may not provide the same level of performance as Cat 6. The latter supports up to 10 Gbps over short distances and has an enhanced frequency of 250 MHz, which significantly reduces crosstalk and interference. These features promote more reliable data transfer in environments where data integrity is paramount.

On the other hand, fiber optic cables represent a high-performance alternative that offers unparalleled speed and bandwidth capabilities. While fiber optics can transmit data over long distances without degradation, the cost and complexity of installation can be prohibitive for many elevator systems. Furthermore, the physical fragility of fiber optic cables can pose additional challenges in maintenance and handling.

In contrast, Cat 6 cables strike a balance between performance and practicality. With easier installation and maintenance compared to fiber optics and superior performance relative to Cat 5e, Cat 6 cables effectively cater to the needs of modern elevator systems. They are capable of handling high data usage and ensuring smooth communication between control systems, which is vital for safe and efficient elevator operation.

Overall, while there are distinct advantages and limitations to each type of cable, Cat 6 cables emerge as a preferable choice for many elevator systems due to their combination of speed, quality, and affordability.

Case Studies: Cat 6 Cables in Elevator Applications

In recent years, numerous case studies have demonstrated the effective integration of Cat 6 cables within elevator systems, highlighting the advancements in connectivity and performance that these cables bring to modern architecture. One notable example can be found in a high-rise building located in Dubai, where the installation of Cat 6 cables transformed the elevator communication and management system.

This building, equipped with a state-of-the-art elevator system, relied on outdated wiring that struggled to support the increasing demand for data transfer and connectivity. Upon switching to Cat 6 cables, the management observed a significant enhancement in the speed of communication between the elevator control systems and the main building software. This upgrade led to a more efficient dispatch of elevators, reduced wait times for users, and improved overall service quality.

Another compelling case study comes from a commercial property in Abu Dhabi, where Cat 6 cables were integrated into the building’s vertical transportation system. Prior to installation, the elevators faced numerous connectivity issues, impacting their performance, particularly during peak hours. Following the use of Cat 6 cables, which provide higher bandwidth and support greater data transmission rates, the property’s management reported a drastic decrease in these connectivity problems. The enhanced performance resulted in smoother operations, allowing the elevators to handle a higher volume of passengers effectively.

These case studies showcase the adaptability and advantages of Cat 6 cables in real-world elevator applications. The tangible benefits, including improved performance metrics and increased user satisfaction, firmly establish these cables as an essential component of modern elevator systems. Companies operating within the industry increasingly recognize that investing in Cat 6 technology not only resolves existing issues but also positions them for future advancements in elevator operation and management.

Conclusion and Future Trends in Elevator Cabling

In evaluating the various aspects of Cat 6 cables specifically designed for elevators, it is evident that these components play a crucial role in enhancing the functionality and efficiency of modern vertical transportation systems. Throughout this discussion, we have highlighted the advantages of using Cat 6 cables, including their superior performance in handling data transmission and their suitability for increasingly complex elevator systems. As buildings evolve into smart environments, the integration of advanced cabling solutions becomes paramount.

Looking ahead, several future trends are set to shape the elevator cabling industry. Firstly, as smart buildings become more prevalent, the reliance on high-speed data transfer will continue to rise. This demand will compel manufacturers like Fahad Cables Industry to innovate and produce cables that not only meet current standards but also anticipate future technological advancements. The collaboration of cabling infrastructure with IoT devices is likely to redefine operational efficiency in elevators, allowing for real-time monitoring and predictive maintenance.

Another trend is the increasing focus on energy efficiency and sustainability in building design. The development of eco-friendly materials and practices in cable manufacturing may significantly influence future cabling solutions. Companies will need to adapt to these environmental considerations by providing products that align with global sustainability goals. Additionally, advancements in materials science may lead to the creation of even more robust and versatile cabling options, enhancing reliability while reducing maintenance costs.

In conclusion, the evolution of elevator cabling, particularly with the implementation of Cat 6 cables, reflects the broader trends in technology and sustainability. As industries strive for efficiency and innovation, manufacturers like Fahad Cables Industry FZE are well-positioned to lead this transformation, ensuring that cabling solutions not only meet the needs of today but also pave the way for the advancements of tomorrow.