- Network Cables

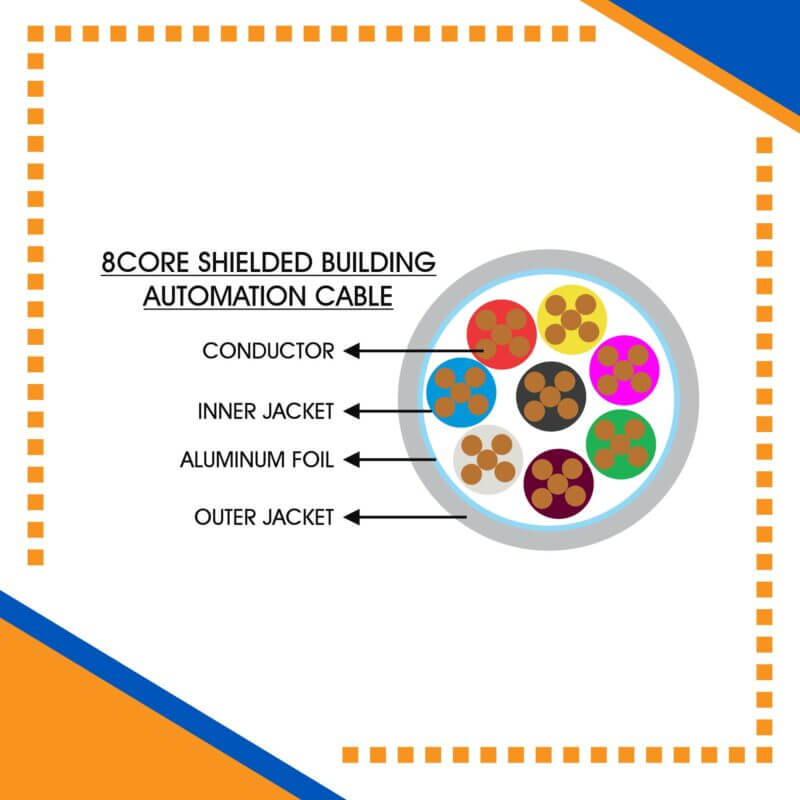

- Control automation Cables

- Data Patch Cord

- fiber optic cable

- Fiber Patch cord Multimode

- Fiber Patch cord Single Mode

- Fiber Pigtails Series

- Coaxial Cables

- security cable wire

- alarm cable

- speaker cables

Exploring Rubber Cable Factories: Fahad Cables Industry FZE in the UAE

Introduction to Rubber Cables

Rubber cables are a type of electrical cable designed for applications requiring durability, flexibility, and resistance to environmental influences. Comprising a core conductor typically made of copper or aluminum, these cables are insulated with rubber, enhancing their physical properties and performance. This distinctive construction makes rubber cables ideally suited for various industries, including construction, telecommunications, automotive, and energy.Rubber Cable Factories

One of the main properties of rubber cables is their exceptional flexibility. They can be bent and shaped without breaking, which is crucial for installations in tight spaces or complex configurations. The flexibility of rubber cables also contributes to their ease of handling and installation, reducing labor costs and time on site. Additionally, these cables can withstand mechanical stress and abrasion, making them a preferred choice for dynamic applications, such as robotics and machinery.

Rubber cables exhibit excellent resistance to environmental factors, which is another reason for their widespread use. They are resistant to moisture, chemicals, UV light, and extreme temperatures. This resistance helps maintain the integrity of the cables in harsh conditions, thereby extending their operational life. Furthermore, rubber insulation is inherently durable, protecting the conductive core from damage due to elements such as water, oils, and various industrial contaminants.

Moreover, the versatility of rubber cables enhances their appeal across multiple sectors. They are available in various sizes and configurations to meet specific electrical load requirements and application preferences. This adaptability makes them an essential component in many electrical systems, ensuring reliable performance and safety. The importance of rubber cables continues to grow as industries seek more robust and long-lasting solutions for their electrical needs.

Fahad Cables Industry FZE: An Overview

Founded in the heart of the United Arab Emirates, Fahad Cables Industry FZE has established itself as a key player in the manufacturing sector, particularly in the production of high-quality rubber cables. Since its inception, the company has emphasized the importance of adhering to international standards and regulations, ensuring that all products meet stringent quality benchmarks. This commitment to excellence is further reflected in the company’s mission to provide cutting-edge cable solutions that cater to the diverse needs of various industries.

The mission of Fahad Cables Industry FZE extends beyond mere production; it encompasses a dedication to innovation. By investing in the latest technology and embracing modern manufacturing processes, the company has positioned itself as a leader in cable production. Its vision underscores the desire to not only meet market demands but to anticipate them, creating products that are both reliable and forward-thinking. This proactive approach has garnered the company a reputation for superior product performance and customer satisfaction.

1.5 mm 2 core rubber cable factories

Introduction to 1.5 mm 2 Core Rubber Cables

1.5 mm 2 core rubber cables are widely used in various electrical applications due to their flexibility, durability, and resistance to weather conditions. These cables are typically employed in both industrial and domestic settings, making them an essential component in electrical installations

When it comes to sourcing 1.5 mm 2 core rubber cables, the factories behind their production play a significant role. Quality control measures are critical to ensure that these cables meet safety and reliability standards. Factories must adhere to strict manufacturing guidelines to produce cables that can handle the demands of different electrical systems. Testing for electrical conductivity, insulation resistance, and overall durability are crucial assessments performed during production.

Within the broader context of the UAE’s manufacturing sector, Fahad Cables Industry FZE holds a prominent position. The company contributes significantly to the local economy by generating employment opportunities and fostering skill development among its workforce. Additionally, its initiatives in sustainable manufacturing practices align with the UAE’s strategic vision for environmental stewardship. By focusing on quality, innovation, and sustainability, Fahad Cables Industry FZE exemplifies the essence of modern manufacturing, demonstrating that businesses can thrive while responsible stewardship is upheld.

As the demand for reliable electrical solutions continues to rise, Fahad Cables Industry FZE remains steadfast in its commitment to development and improvement. This focus not only ensures the ongoing relevance of the company within the competitive landscape but also reinforces its identity as a cornerstone of the UAE’s manufacturing industry.

The Manufacturing Process of Rubber Cables

The manufacturing process of rubber cables at Fahad Cables Industry FZE is an intricate sequence that combines advanced technology and high-quality materials to produce reliable and durable products. The foundation of this process lies in the selection of raw materials, which primarily include high-grade rubber compounds, metal conductors, and insulation materials. These components are meticulously sourced to ensure compliance with international standards and specifications.

Once the raw materials have been procured, the process begins with the design phase, where engineers develop specifications based on the intended application of the rubber cables. This stage is crucial as it dictates the overall functionality, flexibility, and resistance of the cables. Following this, the rubber compounds are mixed with various additives to enhance their electrical and mechanical properties. The mixture is then subjected to a precise heating process known as vulcanization. This step chemically bonds the materials together, giving the cables their exceptional durability and resistance to environmental factors.

After vulcanization, the metal conductors are assembled and coated with the prepared rubber compound. This ensures that the cables possess the right degree of flexibility while maintaining sufficient insulation. The next step involves the extrusion process, where the rubber compounds are forced through a die to form a continuous sheath around the conductors, thereby providing protection from moisture and chemicals.

Finally, quality assurance is an integral part of the manufacturing process at Fahad Cables. Each batch of rubber cables undergoes rigorous testing for electrical performance and durability. This encompasses visual inspections, electrical tests, and mechanical assessments to ensure that every product meets the high standards set by the industry. The culmination of these steps results in a reliable rubber cable suited for various applications, reflecting the commitment of Fahad Cables Industry FZE to excellence in cable manufacturing.

Quality Control Measures in Production

Fahad Cables Industry FZE places a high priority on quality control measures throughout its manufacturing process, ensuring that all products adhere to stringent international standards. The company’s commitment to quality begins with the selection of raw materials, where suppliers are rigorously vetted to guarantee that only the finest inputs are utilized in production. This initial step is crucial, as it lays the foundation for the integrity and performance of the final products.

During the production phase, Fahad Cables employs advanced technology and equipment to facilitate precise manufacturing processes. Automated machinery enhances efficiency while minimizing the likelihood of human error. Quality assurance teams monitor each stage of production, conducting regular inspections to verify that all processes align with predefined quality benchmarks. This proactive approach helps to promptly identify any deviations from the standards, ensuring that corrective actions are taken swiftly.

After the manufacturing phase, Fahad Cables implements an extensive testing protocol, which includes electrical, mechanical, and environmental assessments. The cables are rigorously tested to confirm their endurance, flexibility, and insulation properties, meeting the compliance criteria established by internationally recognized organizations. Additionally, certifications from authoritative bodies further validate the quality and reliability of the products. This rigorous testing not only ensures that the cables can withstand real-world conditions but also provides customers with the confidence that they are purchasing high-quality products.

In conclusion, Fahad Cables Industry FZE’s dedication to quality control is exemplified through a comprehensive approach that encompasses every facet of production. By implementing rigorous testing and certification procedures, the company reinforces its commitment to delivering products that not only meet but exceed customer expectations and applicable international standards.

Applications of Rubber Cables

Rubber cables, particularly those produced by Fahad Cables Industry FZE, play an essential role across various sectors including construction, automotive, and industrial machinery. Their unique properties, such as flexibility, durability, and resistance to environmental factors, make them ideal for a myriad of applications.

In the construction sector, rubber cables are frequently utilized for temporary power connections and lighting solutions. When workers require reliable electricity on building sites, rubber cables can withstand harsh weather conditions, thus ensuring safety and efficiency. Moreover, their flexibility enables easy maneuvering around corners and obstacles, making them suitable for dynamic work environments. Additionally, these cables are often employed in machinery used for concrete mixing and heavy lifting, where heavy-duty performance is crucial.

The automotive industry also benefits significantly from rubber cable applications. These cables are extensively used in vehicle wiring harnesses, ensuring the proper functioning of essential systems such as lighting, power distribution, and communication between components. Their resilience to heat and chemicals makes them perfectly suited for the challenging conditions found under the hood of automobiles. Furthermore, rubber cables contribute to the overall safety of vehicles by providing reliable electrical connections that withstand vibrations and mechanical stresses.

In the realm of industrial machinery, rubber cables find applications in manufacturing, automation, and robotics. The inherent flexibility and resistance to abrasion allow these cables to operate effectively in environments where movement and machinery are prevalent. For instance, they are commonly integrated into conveyor systems and robotic arms, facilitating seamless operations and improving productivity. The use of rubber cables not only enhances the performance of industrial equipment but also prolongs its lifespan, reducing downtime and maintenance costs.

Overall, the versatility of rubber cables produced by Fahad Cables Industry FZE ensures that they are indispensable across various sectors, helping businesses operate safely and efficiently.

Sustainability Practices at Fahad Cables

Fahad Cables Industry FZE is deeply committed to integrating sustainability into its production processes, reflecting a responsible approach towards environmental stewardship. The organization recognizes the environmental impact of cable manufacturing and has implemented several initiatives aimed at reducing waste and utilizing eco-friendly materials throughout their operations.

One of the cornerstone practices of Fahad Cables is their stringent waste management strategy. This initiative includes the recycling of materials involved in the cable production process. By repurposing scrap materials and minimizing by-products, the factory significantly reduces its overall waste footprint. The use of advanced manufacturing technologies facilitates this reduction, allowing for precise material usage and lower emissions during production.

In addition to waste reduction, Fahad Cables focuses on sourcing eco-friendly materials wherever possible. Their cables are designed with an emphasis on sustainability, which involves using non-toxic, recyclable compounds that do not contribute to environmental degradation. This choice not only enhances the product’s marketability but also aligns with the growing demand for sustainable solutions in the electrical industry. Moreover, adopting alternative materials showcases Fahad Cables’ innovation and commitment to meeting global sustainability standards.

Beyond the immediate production environment, Fahad Cables maintains rigorous adherence to environmentally friendly practices, such as energy conservation and pollution prevention. The factory utilizes energy-efficient machinery and implements practices that lower their carbon emissions, contributing to their green credentials. Regular audits and assessments ensure compliance with environmental regulations and help identify areas for further improvement.

Through these multifaceted efforts, Fahad Cables Industry FZE exemplifies a forward-thinking approach to sustainability in cable manufacturing, positioning itself as a leader and model for others in the industry striving to adopt greener practices and promote a sustainable future.

Customer Service and Support at Fahad Cables

Fahad Cables Industry FZE places a significant emphasis on customer service and support, recognizing that the quality of its services play a crucial role in sustaining customer relationships and fostering loyalty. Prior to making a purchase, customers can benefit from tailored consultations that ensure they select the right rubber cables for their specific applications. These consultations are conducted by knowledgeable representatives who are well-versed in the technical specifications and industry standards related to their products.

In addition to pre-purchase consultations, Fahad Cables also provides comprehensive technical assistance designed to address any queries or concerns that customers may have. Their customer service team is readily available via multiple communication channels, including phone, email, and chat, ensuring that help is just a message away. This efficiency in communication not only streamlines the purchasing process but also instills confidence in clients, knowing they have access to support when needed.

Furthermore, post-purchase support is just as vital to Fahad Cables’ customer service approach. The company provides ongoing assistance, focusing on any technical challenges or maintenance needs related to their rubber cables. This commitment to aftersales care demonstrates that Fahad Cables values its customers long after the transaction is complete. By prioritizing technical guidance and effective support channels, the company assures its clientele that expert help is available whenever required.

Incorporating feedback from customers into their business practices is another hallmark of Fahad Cables’ customer service. Listening to client experiences allows the company to continuously enhance its offerings and service delivery, ultimately contributing to improved satisfaction among customers. The breadth of customer service initiatives implemented reflects Fahad Cables’ dedication to maintaining high standards of excellence, which further cements its reputation in the competitive rubber cable market.

Case Studies: Success Stories from Clients

Fahad Cables Industry FZE has successfully collaborated with various sectors to provide cutting-edge rubber cable solutions, demonstrating the versatility and reliability of their products. One notable case study involves a partnership with a major construction company focused on a high-rise building project in Dubai. The developers required robust and resilient electrical cabling capable of withstanding the harsh environmental conditions prevalent in the region. Fahad Cables supplied rubber cables that not only met the stringent safety standards but also enhanced the efficiency of the electrical systems. Client feedback highlighted the cables’ durability and flexibility, significantly contributing to a successful and timely project completion.

Another noteworthy example involves a leading manufacturing facility in Abu Dhabi. The client faced persistent issues with electrical wiring failures due to equipment vibrations and temperature fluctuations, which were adversely affecting production. In response to this challenge, Fahad Cables provided specially engineered rubber cables designed to endure such demanding conditions. As a result, the facility reported a 30% reduction in maintenance costs and a noticeable increase in operational uptime. This success story exemplifies how tailored rubber cable solutions from Fahad Cables can resolve industry-specific challenges.

Furthermore, a partnership with a prominent telecommunications company showcased the advantages of using rubber cables in fiber optic networks. The project aimed to improve connectivity in remote areas of the UAE. Fahad Cables delivered customized rubber insulated cables that facilitated robust performance in outdoor installations. The client experienced enhanced network reliability and customer satisfaction, which underscored the essential role of dependable cabling solutions in today’s high-speed communication landscape.

These case studies reflect the commitment of Fahad Cables Industry FZE to customer satisfaction and innovation. Through effective application and adaptation of rubber cables, the company continues to make significant impacts across various sectors.

Conclusion and Future Outlook

In this examination of rubber cable manufacturing, we explored the operations and innovations at Fahad Cables Industry FZE in the UAE. The company stands as a pivotal player in this sector, combining advanced technology with quality craftsmanship to produce a range of rubber cables that meet various industrial needs. The emphasis on durability and flexibility in manufacturing processes has positioned Fahad Cables as a reliable supplier, well-suited to meet the demands of an ever-evolving market.

As we look towards the future, several trends are expected to shape the rubber cable industry. There is a growing demand for eco-friendly materials and sustainable production techniques, reflecting a broader shift towards environmental responsibility in manufacturing. Fahad Cables Industry FZE is already exploring innovations in this area, aiming to incorporate more sustainable practices into their production lines. This commitment not only enhances their product offerings but also aligns with global standards for environmental sustainability.

Furthermore, advancements in technology, including automation and smart manufacturing, are likely to revolutionize the rubber cable sector. Fahad Cables is keen on investing in these technologies to improve efficiency and reduce production costs, ensuring that they remain competitive. The integration of smart technologies may also enhance quality control and streamline supply chains, further solidifying the company’s position in the market.

In summary, Fahad Cables Industry FZE is poised to take advantage of upcoming innovations and market trends. Their strategic direction indicates a focus on sustainability, technological integration, and responsiveness to market demands. As the rubber cable sector continues to evolve, Fahad Cables is expected to be at the forefront, contributing to advancements within the industry while maintaining their commitment to quality and customer satisfaction.